Watch how Bare Naked Cases are Made

It ain't easy...

Making the thinnest case in the world is an incredible challenge, much more so than regular cases you’re used to seeing.

In fact, our Bare Naked cases are so thin, 0.35mm to be exact, they require plenty of human input in its manufacturing process since modern machines can’t handle it with enough care to produce a flawless case.

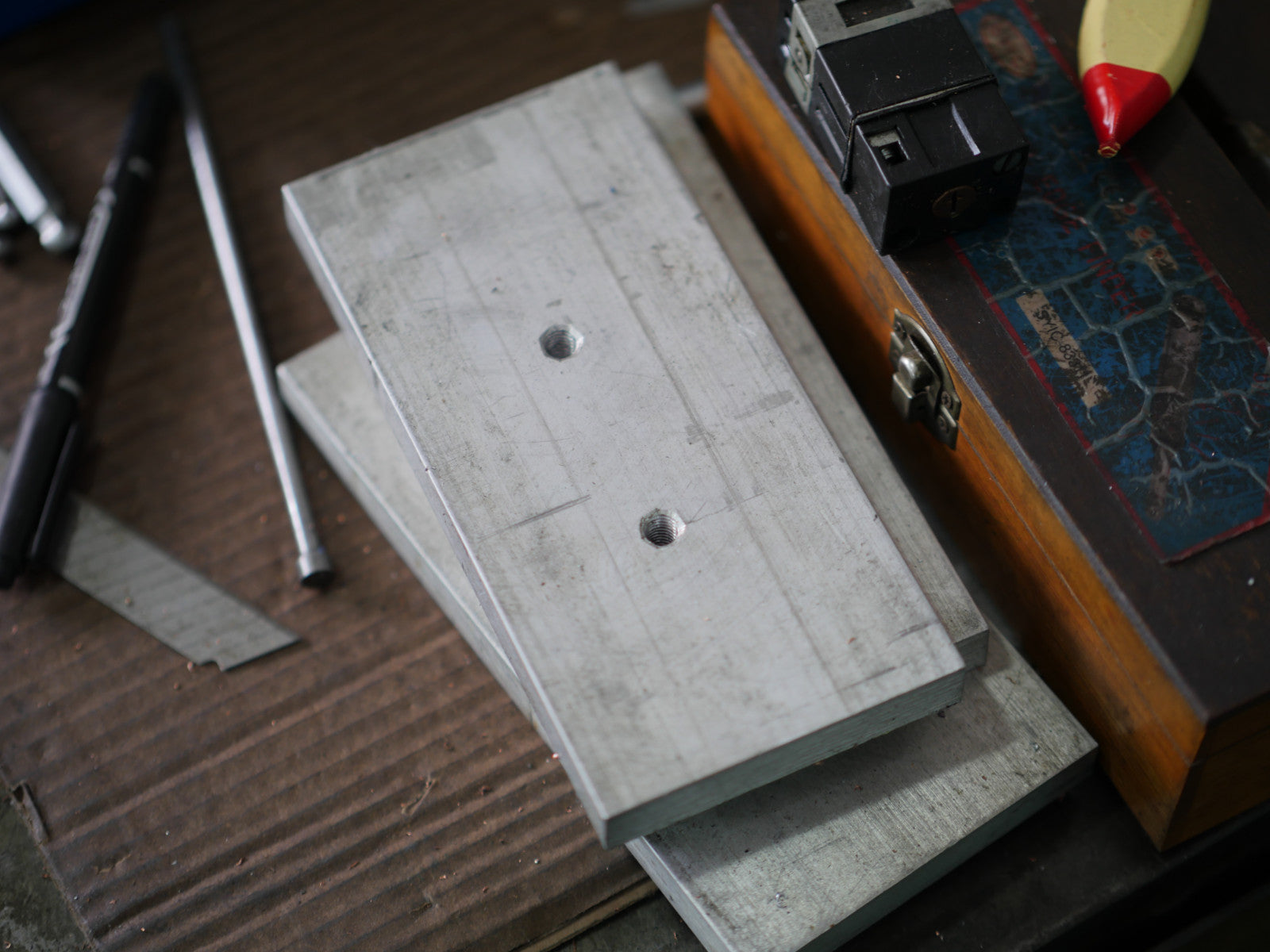

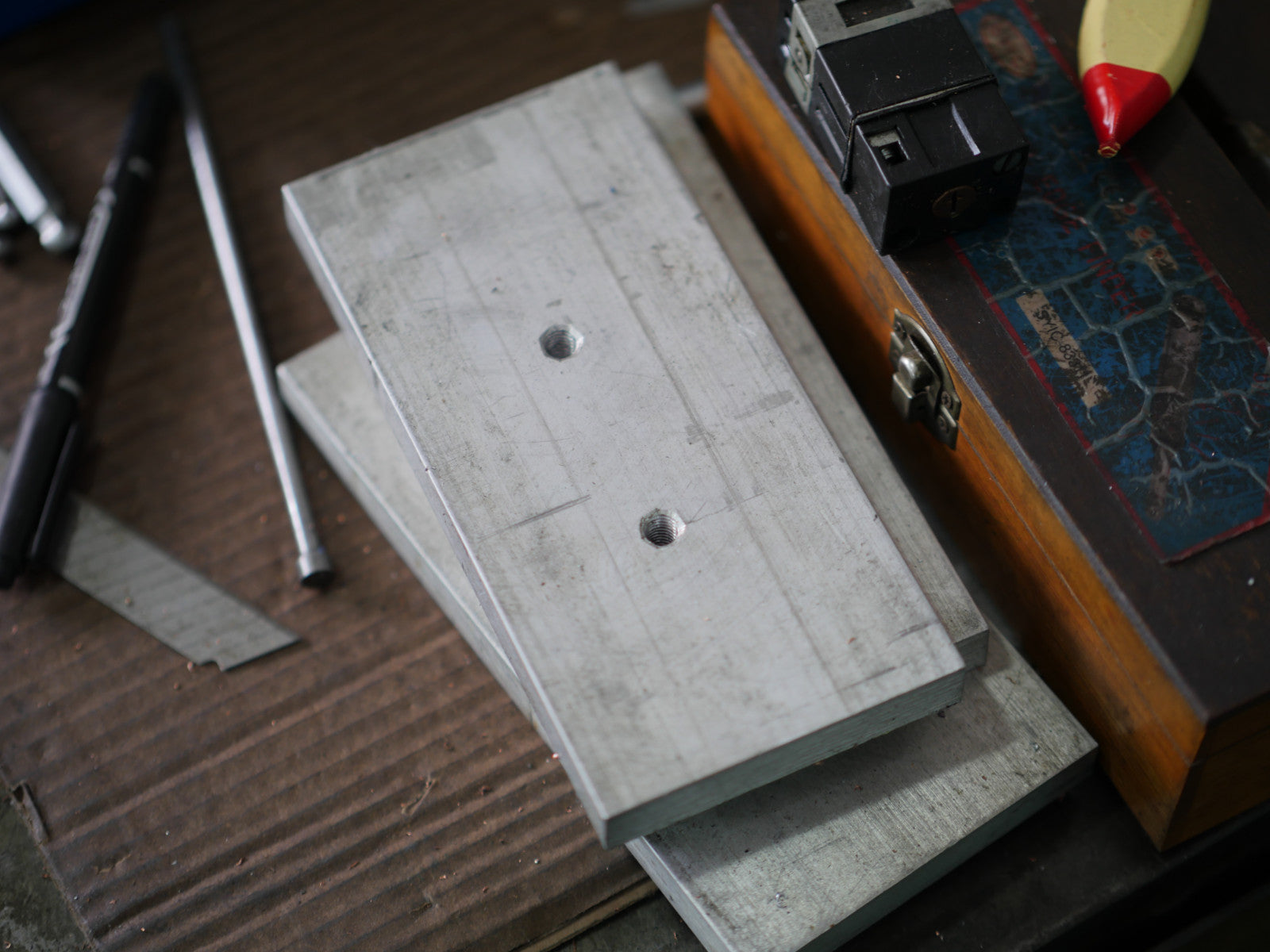

Moulds start life as boring slabs of metal that'll be subjected to loads of beating very soon, turning it into something that looks a little more pretty.

After careful machining with CNC machines that are so precise, people would've called them Gods 10 years ago, we get this - a "dummy", both figuratively and literally.

Remember what this is called, 'cos we'll get back to this in a minute.

Moulds start life as boring slabs of metal that'll be subjected to loads of beating very soon, turning it into something that looks a little more pretty.

After careful machining with CNC machines that are so precise, people would've called them Gods 10 years ago, we get this - a "dummy", both figuratively and literally.

Remember what this is called, 'cos we'll get back to this in a minute.

The "base" mould

To make our Bare Naked case, we need two moulds:

the dummy, and the base.

The base is where the liquid resin is placed, and before it has time to solidify,

the dummy is pressed down on it to shape the resin, matching whatever device the case is made for.

These moulds have reached the end of their lives, not 'cos the model they're made for has gone obsolete, but because with each repeated use, its measurements change in microns.

So to ensure every case is a perfect fit for your device, we have to make new moulds on top of cleaning existing ones regularly. Oh, these moulds aren't cheap to make too...

and how many moulds do we use for one production run?

All these "spent" moulds will be cleaned, recycled, and made into new metal blocks to make more moulds.

These moulds have reached the end of their lives, not 'cos the model they're made for has gone obsolete, but because with each repeated use, its measurements change in microns.

So to ensure every case is a perfect fit for your device, we have to make new moulds on top of cleaning existing ones regularly. Oh, these moulds aren't cheap to make too...

and how many moulds do we use for one production run?

All these "spent" moulds will be cleaned, recycled, and made into new metal blocks to make more moulds.

Quality Control

Before mass production, the initial run is checked by eagle-eyed QC experts to reveal any defects with the molds or resin.

It is a painstaking process that is repeated at the end of production for retail-ready cases.

Finishing Touches

We pay attention to detail - the manufacturing process of our Bare Naked cases create "overhangs" at the molding lines, and we have to get rid of them. Problem is, our Bare Naked cases are far too thin for machines to clean up this mess.

So what do we do?

We trim them by hand

Flawless Finish

Made for your pleasure

It is this combination of precise machining & human touch that makes Bare Naked cases hug your device so perfectly, with cutouts so precise, it’ll literally make you whisper “wow...” while wondering why you didn’t get Bare Naked sooner.

Looking for another type of case?

Check out our other cases

Bare Skin Case

Full-grain Leather case for iPhone

Luxurious leather case that embodies your unique story through the language of patina.

Bare Armour Case

Slim shockproof MagSafe case for iPhone

Protect your iPhone from hard-hitting drops while keeping bulk to a minimum.

The Bare Case

The thinnest MagSafe case for iPhone

The Bare Case gives you the perfect balance of protection while keeping your iPhone as thin as possible.